Company is located at N.H.-8 at Palsana, Surat, Gujarat. The company is having land area of 10133 square meter. Total built up area of approx 26000 square feet which includes process area, warehouse, laboratory and office area.

Integrated with industry's well renowned companies machineries and work force with very good technical know-how and experience, gives us an installed capacity of 7500 MT/Annum. We cater almost every discipline using plastics.

Variety of our production equipments allow us to match each product to the right process and consistent quality in shortest lead time. Our works always remain a special experience for polymer compounding.

We are having state of the art twin screw compounding extruder from world's leading machine manufacturer Werner & Pfleiderer (Germany) and Toshiba Machine Co. Ltd. (Japan).

| Sr. No. | Make | Model | Machine Specification |

|---|---|---|---|

| 1 | Werner & Pfleiderer | ZSK-92 | Co-rotating Twin Screw Extruder |

| 2 | Toshiba Machine Co. Ltd. | TEM-100 | Co-rotating Twin Screw Extruder |

| 3 | Multiplast Machines Pvt. Ltd. | TSE-70 | Co-rotating Twin Screw Extruder |

| 4 | Hi-Tech Engineers | MPTC-70 | Co-rotating Twin Screw Extruder |

| 5 | PIV Machines Ltd. | PIV-90 | Co-rotating Twin Screw Extruder |

| 6 | Bharat Electric Works | KM-75 | 75 Litre Intermix Kneader with Automated Palletizing Line |

| 7 | Bharat Electric Works | KM-35 | 35 Litre Intermix Kneader with Die Face Cutting Line |

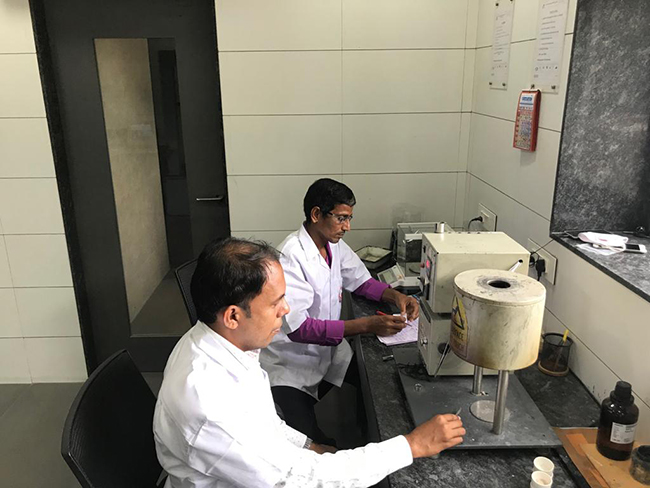

Padmanabh has a dedicated testing laboratory for all polymers testing under ASTM-D standard. In house molding facility ensures controlled manufacturing of test specimen.

In our quality control laboratory we are checking quality of products that we are producing at regular interval.

| Sr. No. | Name of Equipment | Test |

|---|---|---|

| 1 | Universal Testing Machine | Tensile, Flexural, Elongation |

| 2 | Impact Tester | Izod, Charpy |

| 3 | Notch Cutter | Izod |

| 4 | Heat Distortion Bath | HDT |

| 5 | Melt Flow Index Tester | Melt Flow |

| 6 | Accurate Weighing Balance | Weighing |

| 7 | Laboratory Oven | Moisture Content |

| 8 | Muffle Furnace | Filler Content |

| 9 | Injection Molding Machine (SP 80) | Color & Test Specimen |

| 10 | Melting Point Apparatus | Melting Point |

| 11 | pH Meter | pH Measurement |

| 12 | Lab Mixer | Mixing |